- info@fxlion.net

In general, most of the batteries we use on a daily basis are made of smaller battery cells. These make up the capacity and voltage of a battery. The capacity is a measure of quantity, in this case the quantity of electric charge, the battery cells can hold for a given time. Therefore, the capacity must be measured in the lab.

In order to understand a battery’s ability to power electronic equipment, we need to understand how cell combinations work in the first place. Every electronic device needs a voltage and current to get running. The voltage is a measure of how much pressure electrons need to move through a conductor. Electric current is a measure for how much electric charge needs to be applied for the electrons to move.

To build a battery, we need to understand how much voltage and how many amps our electrical equipment needs to get running. In the film industry there are some voltage standards that evolved.

A single battery cell, that is commonly used to create such batteries is a 18650 Lithium-ion cell with a rated voltage of 3.7V (The cell’s full power voltage is 4.2V). These cells also come with different capacities. Now there are two possibilities how to connect more cells together; in parallel or in series. This means that you put both plus and minus terminals of the two together or you put the plus of one battery to the minus terminal of the other. These two ways either change the capacity or the voltage.

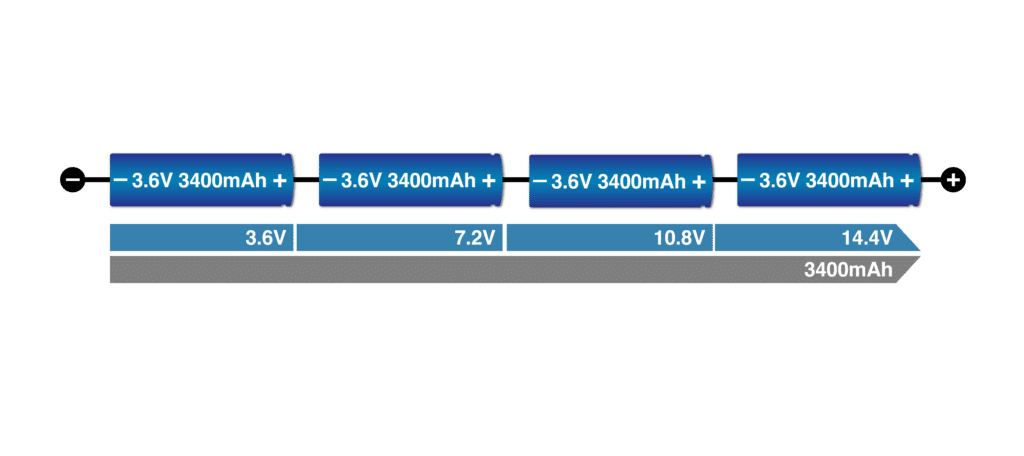

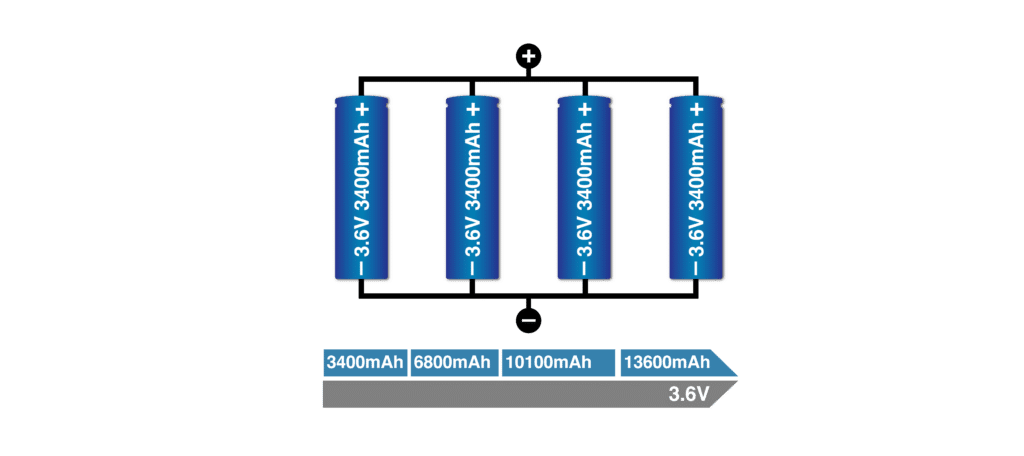

Let’s say we have four 3.6V cells with a capacity of 3400mAh (3.4Ah) and we connect them in above mentioned ways.

Connection in Series

The Voltage has a factor of 4 but the capacity stays the same. You will get a rated voltage battery of 14.4V with a capacity of 3.4Ah.

Connection in Parallel

The Voltage stays the same but the capacity has a factor of 4. You will get a rated 3.6V battery with a capacity of 13.6Ah

By taking this basic knowledge further we now can put together any configuration. There are standard and higher power cells that can be used to achieve batteries with a higher discharge current.

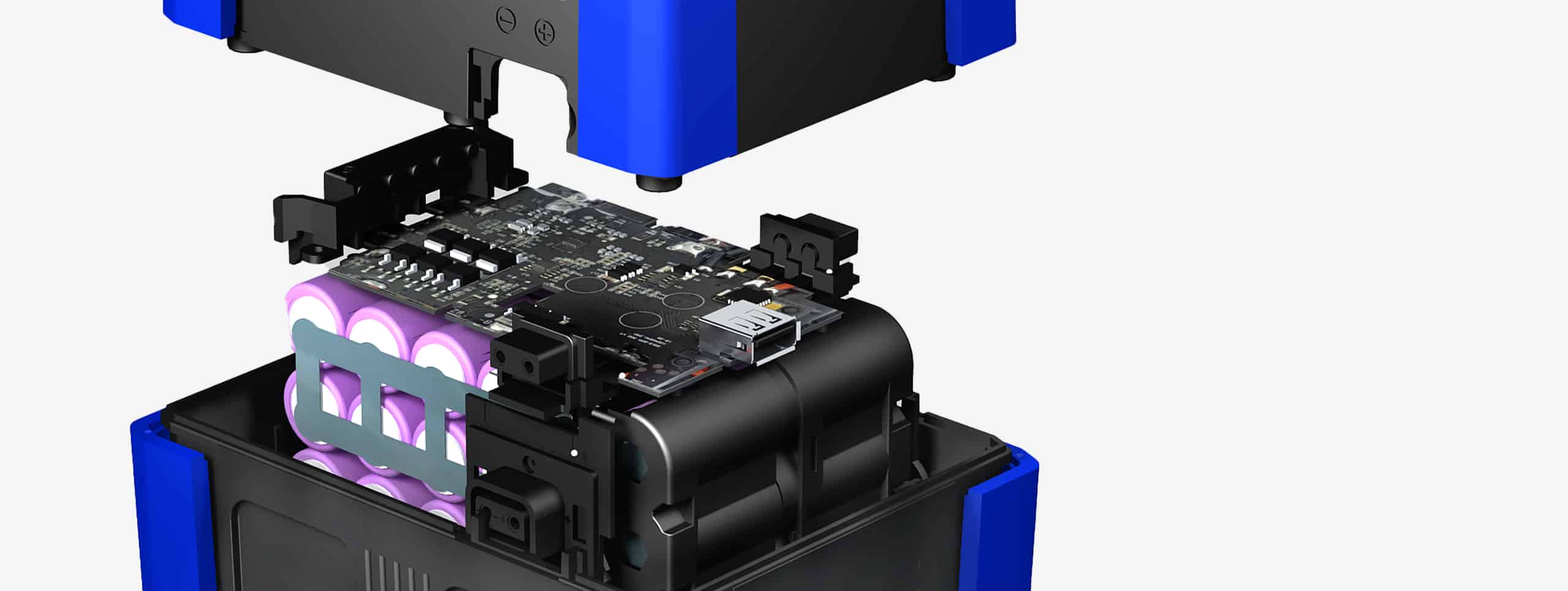

Our BP-M300 – High Power Square Battery has following specifications: 14.8V 20.4Ah 300Wh

The cells that are used have a nominal capacity of 3500mAh. The minimum capacity is 3400mAh. That’s what we use for our calculation.

The configuration is 4S6P (4 in series and 6 in parallel). With this knowledge we are able to do following calculations:

6 x 3400mAh = 20400mAh = 20.4Ah

4 x 3.7V = 14.8V

If we want to know the capacity in Wh (Watthours), we need to make this calculation: Battery Voltage (V) x Capacity (Ah) = Capacity (Wh)

14.8V x 20.4Ah = 301.9Wh ~ 300Wh

When a battery is being used, the voltage drops in relation to the current that is being drawn. The more current you draw from a battery the more voltage loss you will experience. Ending at a point where the voltage is too low to power your equipment, the battery must be recharged.

So what does this mean for above mentioned 4 batteries? We need at least 16.8V charging voltage (4.2V x 4 = 16.8V). After the battery is charged with a constant current – at 90% capacity the voltage switches to a constant level and the current drops.

The slower you charge a battery (= with less current) the longer your capacity will hold. Because of the many cells in a battery pack, the charger also needs to balance those, that every cell reaches its nominal voltage. This is built into the batteries BMS (explained below)

This calculation has probably already been made and is shown on the battery’s label or specifications.

Energy (Wh) = Battery Voltage (V) x Capacity (Ah)

Voltage is measured in V (Volts), capacity in Ah (Amphours) and energy in Wh (Watthours)

example:14.8V x 20.4Ah = 301.9Wh ~ 300Wh

This calculation is basic knowledge for calculating how long a battery with a given capacity will power an electrical device. This calculation should be made if the power consumption of the battery is less than 50% of the battery’s capacity.

Running time (h) = Capacity (Wh) : Power (W)

Running time is measured in h (hours), capacity in Wh (Watthours) or Ah (Amphours) and Power in Watts (W)

example: we have a 300Wh battery (Capacity) and a LED light with a power draw of 100W (Power). 300Wh : 100W = 3 h

When the power consumption of electronic equipment is less than 50% of the battery’s capacity, the theoretical running time tends to be pretty accurate. But as soon as you get over these 50% the voltage loss because of higher current draw and temperature becomes very noticeable. Therefore a more accurate running time can be calculated using 80% of the battery’s capacity instead of a 100%.

Running time (h) = 0.8 x Capacity (Wh) : Power (W)

Capacity is measured in Wh (Watthours), Power in W (Watts) and Running time in h (hours).

example: we have a 300Wh battery (Capacity) and a LED light with a power draw of 150W (Power).

0.8 x 300Wh : 150W = 1.6 h

if we use the regular formula you can see the difference:

300Wh : 150W = 2 h

In the end there is no way to accurately predict the running time of a battery as many factors have an influence. But it is surely a good starting point.

This is an important calculation as the batteries will have a maximum working current. So you should not only use the running time calculation but also this one. We always show this information for every product. Always check that the battery’s working current is the same or higher than the electronic device it needs to power!

Electric Current (I) = Power Draw (P) : Running Voltage (V)

Power is measured in W (Watts), Voltage in V (Volts) and Current (I) in A (Amps)

example: we have an LED light with a power draw of 100W and a 14.8V battery (as the equipment runs on this voltage) that we’d like to use. If your equipment uses 26V you need to adjust the value. Voltage is measured in V (Volts), electric current in A (Amps), Power in W (Watts)

100W (P) : 14.8V (V) = 6.75A

100W (P) : 26 (V) = 3.84A

As you surely noticed, the current that is needed gets smaller, as the Voltage increases. This is why many manufacturers develop higher voltage inputs for high power equipment, as you can still run it on batteries easily, because the load on the battery is very small, but the voltage very high.

Safety is a big concern when we work with electricity. As lithium-ion batteries get warm when overloaded, they could start to burn. So they need a dedicated protection circuit that measures voltage and current. This sounds very simple, but a lot has to be considered when designing a protection circuit. Imagine plugging a higher voltage charger into your battery – without a protection it would probably start to burn. If you could limit the input voltage or stop a higher voltage from even entering the battery circuit you can protect the battery (and others) from being damaged.

This circuit is also called BMS – Battery Management System. All our batteries feature this protection circuit. We protect our batteries from: over-current, over-charge, over-discharge and over-heat. You could even put the plus and minus terminal together, thus shorting the battery. The BMS will kick in to cut off the voltage and you’re safe.

When a battery pack is assembled there is a micro current flowing at all times. One reason is the protection circuit which needs to be powered, as well as other factors. Our goal is to keep this as low as possible. So even if not in use, your battery will get totally discharged at one point.

There are a few things you can do to protect your batteries from damage.

This Question cannot be answered right away. First you have to think about which equipment you may want to power from batteries, and how long they should last in the best case. This means:

The equations to calculate these values can be found above. If you answered this question we have something to start with.

First you know which voltage you need (14.8V / 26V / 48V) and the current load of the equipment (measured in Amps)

You can now tell which batteries could work with your equipment when looking at the voltage and current level of each battery. With these values you can calculate the needed running time. Therefrom it is up to you. You can choose a battery with the most capacity or one that just works for the minimal time you need it.

For further options, we offer different adapter plates and Power Stations that allow you to easily transform the voltage or capacity from 2 or 4 more batteries, to power even bigger equipment (in terms of Power). If you still have any questions, just leave us a message and we get back to you.

Hopefully this guide helped you understanding how the technology of batteries work and how to choose what fits your needs best.